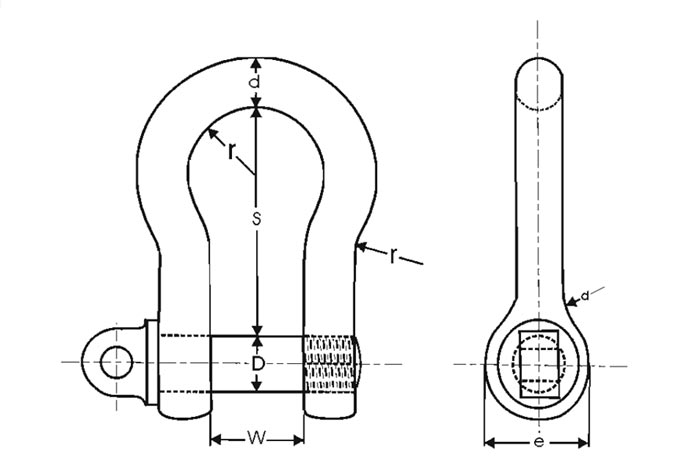

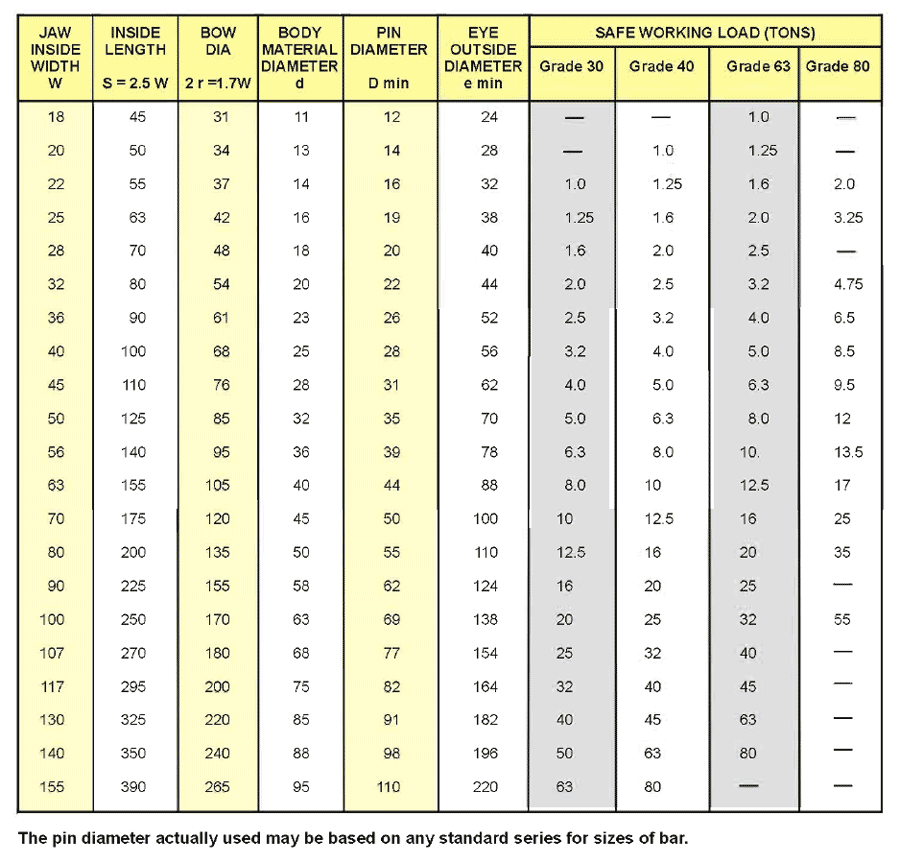

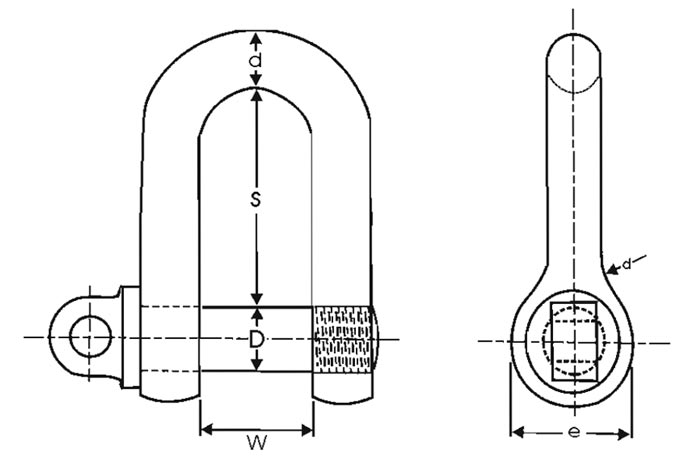

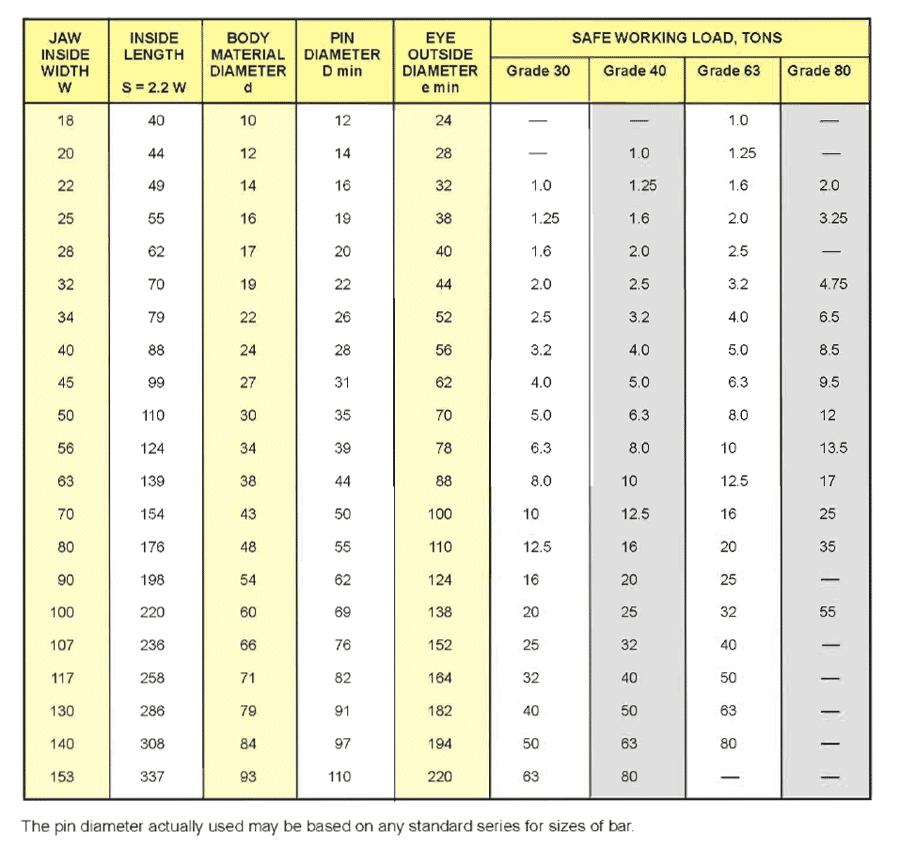

d & Bow shaCKLEs

Crane hooks are critical components in heavy lifting equipment and are specifically designed to ensure safe and efficient material handling. Here are the key features of crane hooks used in heavy lifting Here's a breakdown of the specifications and key features that manufacturers typically provide or adhere to:

Specifications

Material

Forged carbon steel, alloy steel, or stainless steel

Common Types

Anchor (Bow) and Chain (D) shackles

Pin Types

Screw pin, bolt-type (with nut & cotter pin), round pin

Size Range

Typically from 1/4" to over 3" (body diameter)

Working Load Limit

From 0.33 tons (300 kg) up to 1,000+ tons for heavy-duty types

Safety Factor

min. 4:1 with the highest material grade

Standard Compliance

ASME B30.26, ASTM A952/A952M, EN 13889, DNVGL-ST-0378

Finish Options

Galvanized, self-colored, painted, or zinc-coated for corrosion resistance

Key Features

High Load-Bearing Capacity

Shackles are designed to handle very heavy tensile forces. Properly rated for critical lifts in construction, shipyards, and offshore oil platforms.

Material Strength & Toughness

Alloy steel shackles are quenched and tempered to provide high strength and toughness.

Versatile Connection

Used to connect lifting slings, chains, wire ropes, hooks, and lifting lugs. Anchor (bow) shackles allow for multi-directional loading; D shackles are for inline loads.

Ease of Use

Screw pin shackles are fast to attach and detach. Bolt-type shackles are more secure for long-term or safety-critical applications.

Corrosion Resistance

Galvanized or stainless shackles withstand harsh environments including marine and offshore.

Inspection-Friendly

Visual inspection possible for pin wear, body deformation, corrosion, or cracks. Must be removed from service if any signs of damage per safety standards.

D Shackles

Bow Shackles